Tea prices have remained in the downtrend for some time now and though prices have improved a bit this year following a fall in production in all the major growing regions except Sri Lanka, prices for tea of several origins still remain low. The tea industry, which has seen a continuous run of rising costs and lower returns, has thus turned to cutting cost of production as a way of maximizing benefits.

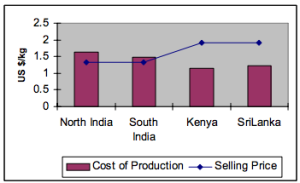

Among the teas of different origins, Indian teas are the ones, which have very high cost of production. The cost of production for 1 kg of tea in North India is US$1.62/kg and in South India, it is US $1.48/kg, while in Kenya, it is only US $1.16/kg for the estate sector and US $1.10/kg for the smallholders and in Sri Lanka, it is US $1.23/kg.

However while comparing the selling cost of these teas it can be found that Kenyan and Sri Lankan teas currently fetch the highest price of nearly US $1.92/kg. Prices for Indian teas still remain at levels of US $1.32/kg.

Between the two types of manufacturing, CTC manufacturing requires only half as much of labour as that of orthodox. As 90 % of India’s tea production is of CTC type, India stands to benefit but still Indian production costs are high because of the high social costs involved in tea production by the estate sector. In India, approximately 75 % of the area under tea cultivation is with the estate sector in contrast to Sri Lanka, where 55 % of the plantations are held by the estate sector.

Factors contributing to cost of production

In order to initiate cost cutting measures, a thorough knowledge about the various contributors to the production cost is necessary. So looking into this part, it can be seen that among the costs incurred by the tea industry, the major ones are those that involve the cultivation costs, manufacturing costs and social costs. Social costs however are limited to large plantations, which provide education, health care, food, sanitation and recreational facilities for the workers. The small growers do not incur such costs. Taking the cultivation costs alone into consideration we can find that tea is one of the most labour intensive agricultural activities and plucking is the one of most labour intensive among the operations involved in production. Nearly 70 % of the labour involved in tea production is used for the plucking operation and approximately 40 % of the cost of production of tea goes into payment for the labour involved in plucking operation. Thus a cost cutting measure in this part of the operation would help in significantly reducing the cost of production.

Labour efficiency

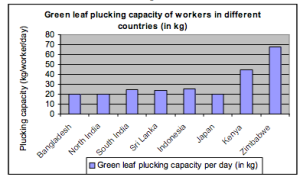

To be able to analyze the ways of improving labour efficiency in plucking, it is essential to know about the factors influencing the efficiency of the labour force. The various factors influencing labour efficiency are the yield of the crop, plant density, age of the plant, height of the plant, jat (Assam or China jat), climatic conditions (which influences the yield) and topography. The efficiency also varies according to the physique and psychology of the workers. The wages and incentives given to the workers also influence the efficiency often. For example in India, during the peak season when production is high, the plucking efficiency is high if additional perks are provided for every extra kg of leaf plucked. In countries like Kenya and Zimbabwe the quantity of leaf plucked is high per worker as the family members of the workers are allowed to assist the worker in plucking.

Improving efficiency

Mechanization is one of the effective alternatives that can reduce costs but in countries like India and Kenya where a large number of people are employed in the plantations, they feel that this is a major threat to their livelihood. Thus they oppose it. For example, in Kenya the current stand off between the various workers unions and the tea growers associations is due to this problem. Big companies in Kenya like the James Finlays are trying to bring in more mechanization into their estates as a cost cutting measure, while the 800, 000 odd workers of Kenyan tea industry are against the initiative, as they fear that they would lose their livelihood.

In some regions of the world however labour availability is lesser and it is costlier also. Some regions in countries like India and Sri Lanka may witness a situation of labour shortage in future as the labour force is migrating towards other jobs, which are easier and more lucrative in terms of earning. In such situations where human labour is very costly, alternative ways or means can be brought in where in a balance would be created, like that of mechanization. At this point we must take into consideration, the factor that even if mechanization were there, the machines involved in plucking operation would need human labour for operation. And with the increase in mechanization and computerization, more skilled manpower would be needed and employment opportunities for the skilled work force would be higher against the current opinion of the striking workers.

Mechanization can be brought in at various degrees. Currently in India using of plucking shears give a helping hand during the rush season when crop output is high and there is a shortage of labour force. Hand operated plucking shears can increase the plucking efficiency from approximately 25 kg per worker per day to nearly 100 – 200, but while using plucking shears, in order not to compromise on the quality the coarse leaves which are harvested, along with the two leaf and bud should be removed manually. Mechanization can be taken to a greater extent in future with improved shears, which are motorized and self-propelled. Motorized mechanical portable type shears can harvest 300 to 450 kg per day if it is operated by a single person and it can harvest 700 to 1500 kg leaves per day when operated by two people. Self-propelled shears can harvest 2000 to 3000 kg of leaves per day thus increasing efficiency by several times. However as the degree of mechanization increases, the crop yield gets affected. Integrated schedules of hand plucking and shear harvesting can prevent reduction in crop yield and help in maintaining the crop cycles.