Every pursuit needs a stepwise approach, which would help in achieving the goal in a quicker pace. The tea industry for some time now has been striving to cut down costs in the wake of tea prices trailing behind production costs. Efforts are being taken to cut costs in every operation from field to manufacturing units. However, tea industry in India is as diverse as Indian culture itself and there are a number of grades of tea, the cost of production of each varying according to the methods involved in manufacturing. Teas produced in different regions in India also carry different cost tags. Till now though costs incurred for tea production in North and South India have been estimated, they have not been specific to the different kinds of plantation establishments. Hence before taking up any cost cutting measures, forming a clear picture of the costs incurred for various operations is very much essential.

Now the cost audit branch of Ministry of Company Affairs (MCA) has issued a directive to Institute of Cost and Works Accountants of India (ICWAI) to bring in mandatory audit for 38 large tea estates under sub-section (i) of Section 233B of the Companies Act, 1956. This and a similar move to find the exact costs involved in tea production in small tea gardens in different parts of India would be of much use when it comes to choosing the areas, which need cost reduction. Cost audit system doesn’t help in tax collection alone. It gives a clear picture of costs incurred. In fact this act of studying the expenditure pattern should have been the first step before going in for taking up cost cutting measures but though it has come a bit late, it is expected to be of vast importance. Here is an appraisal of the various efforts taken up to cut down costs and the initiative taken to bring about a precise estimation of the costs involved in tea cultivation, that has followed the former though it should have been the predecessor.

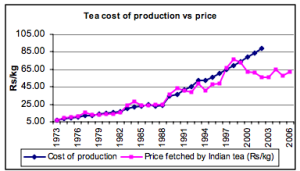

Evaluation of cost – price gap

The tea industry started raising a hue and cry over increasing costs when the prices fetched by tea started declining and when the realizations fell and sometimes even went negative. The following graph shows the gap between cost of production and average prices of Indian tea, fetched in the domestic auction centers. It can be seen that the gap has widened in the recent years. It is also evident that while the cost of production has been on a continuously increasing trend, prices have declined and are well below the production costs. Though it can be seen that the prices during the first six months of this year have recovered from last year’s levels of Rs.58.06/kg and have reached Rs.62.14/kg, these prices are far below the estimated production costs.

Source: International Journal of Tea Science Vol.2 (1&2), 2003 and Tea Board of India.

However, it should be noted that the production costs are estimated figures and it varies widely depending upon the place and type of tea produced. This is where cost analysis would come in handy to assess the exact situation.

Advances in cost cutting initiatives

When prices started falling, the industry woke up to the fact that production costs are running high and their realization is dwindling. They started looking into areas that needed a reduction in expenditure. A few of the operations that attracted their attention were taken into consideration and they started analyzing the ways in which the costs incurred could be reduced. Consequently the following steps are being taken:

- A massive rejuvenation package is to be operational from November 2006 through which the old low yielding tea plants would be removed and the gardens would be replanted with new high yielding clones thus increasing the output obtained per unit input.

- There have been efforts to divert funds from Government schemes to the plantations to provide facilities like health, sanitation and drinking water to the workers. This would help reduce the social costs incurred by plantation managements for providing these facilities thereby reducing their social cost burden.

- Studies are being taken up to improve labour efficiency in labour intensive operations like plucking by providing mechanical tools to the workers. This would combine human workforce and mechanical tools to get maximum efficiency without compromising on the quality of leaves and productivity of tea bushes.

- Efforts are being taken to improve efficiency of tea processing machinery so that energy input is effectively utilized. IIT Kharagpur has been assigned by the Tea Board of India, with the task of modernizing and improving the manufacturing facilities in Darjeeling tea factories, most of which are over a century old in order to improve efficiency.

- Taking a diversion from the above said initiatives, some of the plantation managements have been looking into cultivating other crops in tea gardens along with tea buses in order to effectively utilize space and improve income through other sources. Efforts are also on to encourage tea tourism so that the producer earns through other sources thus minimizing his loss in tea cultivation operations.

- Apart from these, it is seen that judicious application of fertilizers can reduce costs to a significant level.

After all these measures taken up by the industry to cut costs, now has come the initiative by the government that should have come earlier. Though it is like going back to study the root cause of the problem after taking up many successful or unsuccessful attempts to solve a problem, it is still not too late. Initially large gardens have been brought into the ambit of cost audit system. The audit would cover roughly around 200 tea gardens, i.e., 40% of the total area under tea cultivation in India. This statutory audit is to include extracting data and information on exact `costs’ and monetary profitability. Till now only 38 large tea plantations with a minimum annual turn over of Rs.10 crores have been covered under this system. If this is to be exercised in other plantations also, this auditing would help the industry in getting a clear picture about how much of expenditure goes into what operation and location and establishment specific expenditure details. It would be helpful for the government when it comes to fixing subsidies and monetary aids in case there occurs any crisis in the industry.